CNC Lathe Turning Centres.

High quality precision components facilitated by our range of 2-axis CNC lathes:

Integrated touch sensitive control panel

Pre-loaded anti-backlash ball screws on all axes

Single seat of ‘Boxford CAD/CAM Design Tools’ allowing import of multiple formats including: 3D CAD files, JPEG, BMP & PCB Gerber files.

Interlocked solenoid guarding for safe usage

Precision self-centring 3 jaw chuck

12 months warranty

Slant bed construction

Integrated machine electrics

160TCLi

Bench top PC controlled CNC lathe

Ø160mm swing over bed.

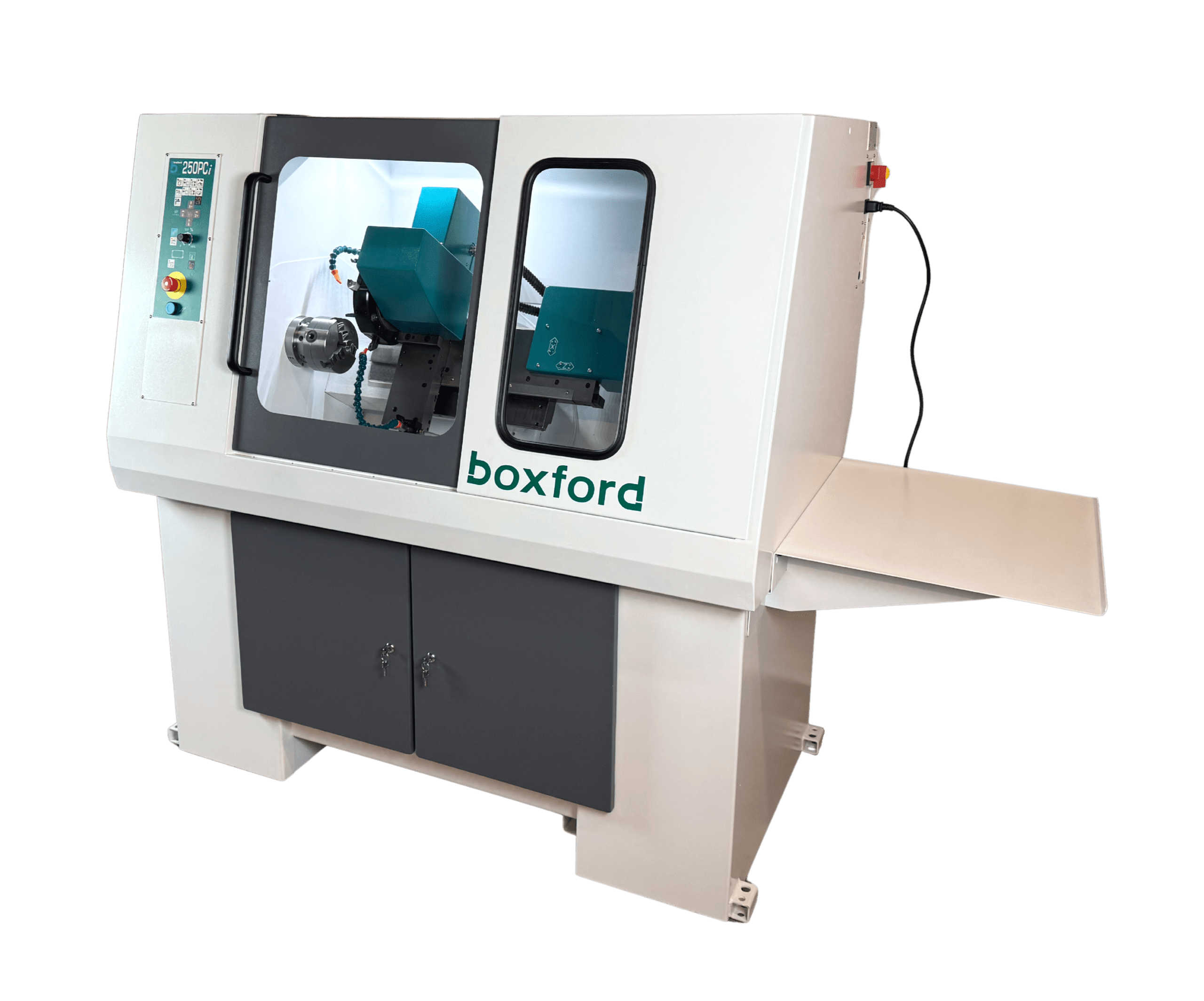

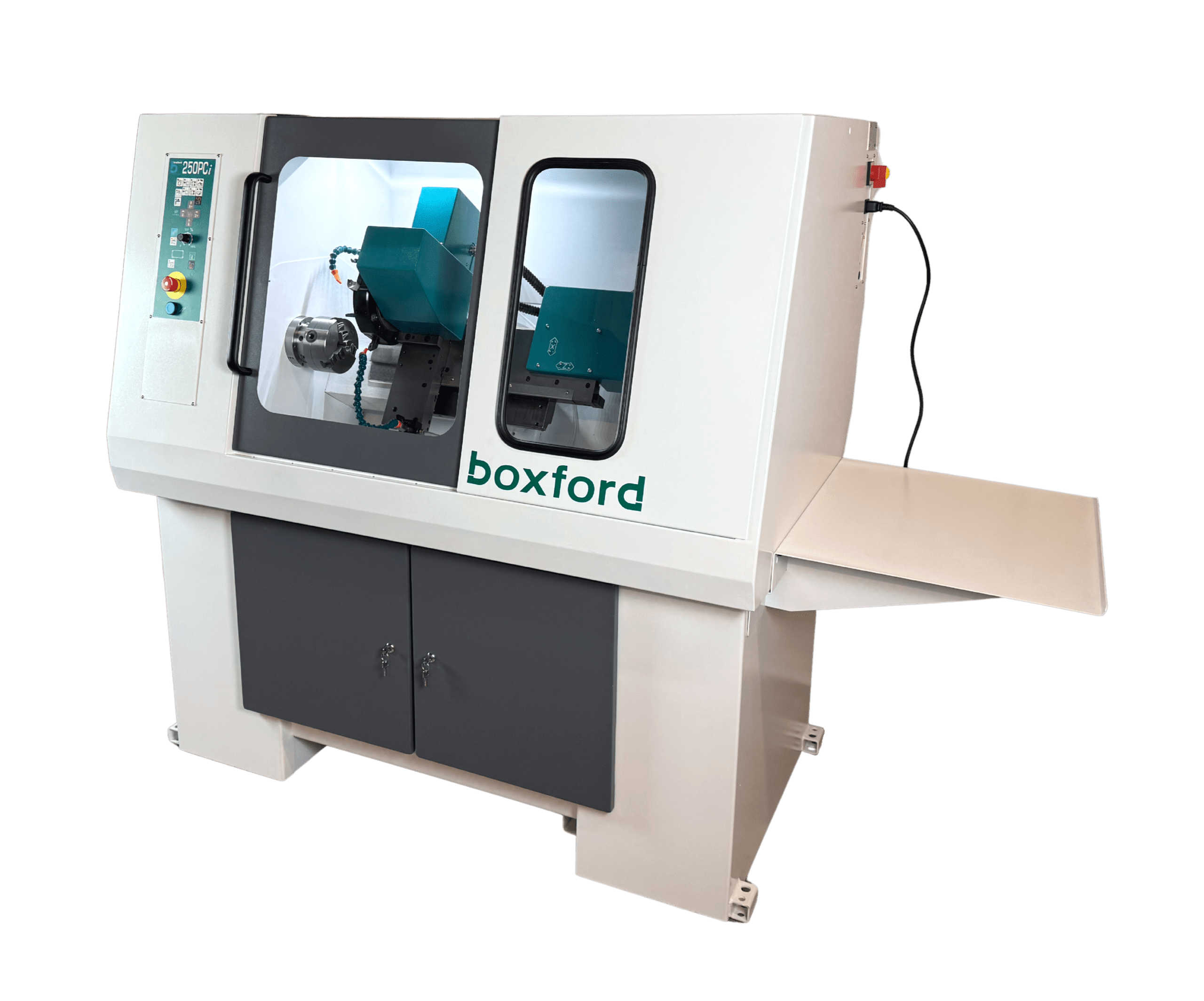

250PCi

Floor standing PC controlled CNC lathe

Ø250mm swing over bed Spindle bored to pass Ø35mm.

Precision dovetail slide construction.

Ø125mm precision self centring chuck.

1 shot integrated lubrication system fitted as standard.

Flood coolant fitted as standard.

Machines mild steel, alloys, plastics and other synthetic materials to close tolerances.

Integrated lockable storage cupboards

Includes removable laptop shelf

POA

Included / Optional accessories

Accessories for Boxford CNC machining centres including:

- Comprehensive tooling set

- Automatic pneumatic chuck

- Manual tailstock steady

- Automatic pneumatic guard

- Robot connection port for FMS/CIM integration

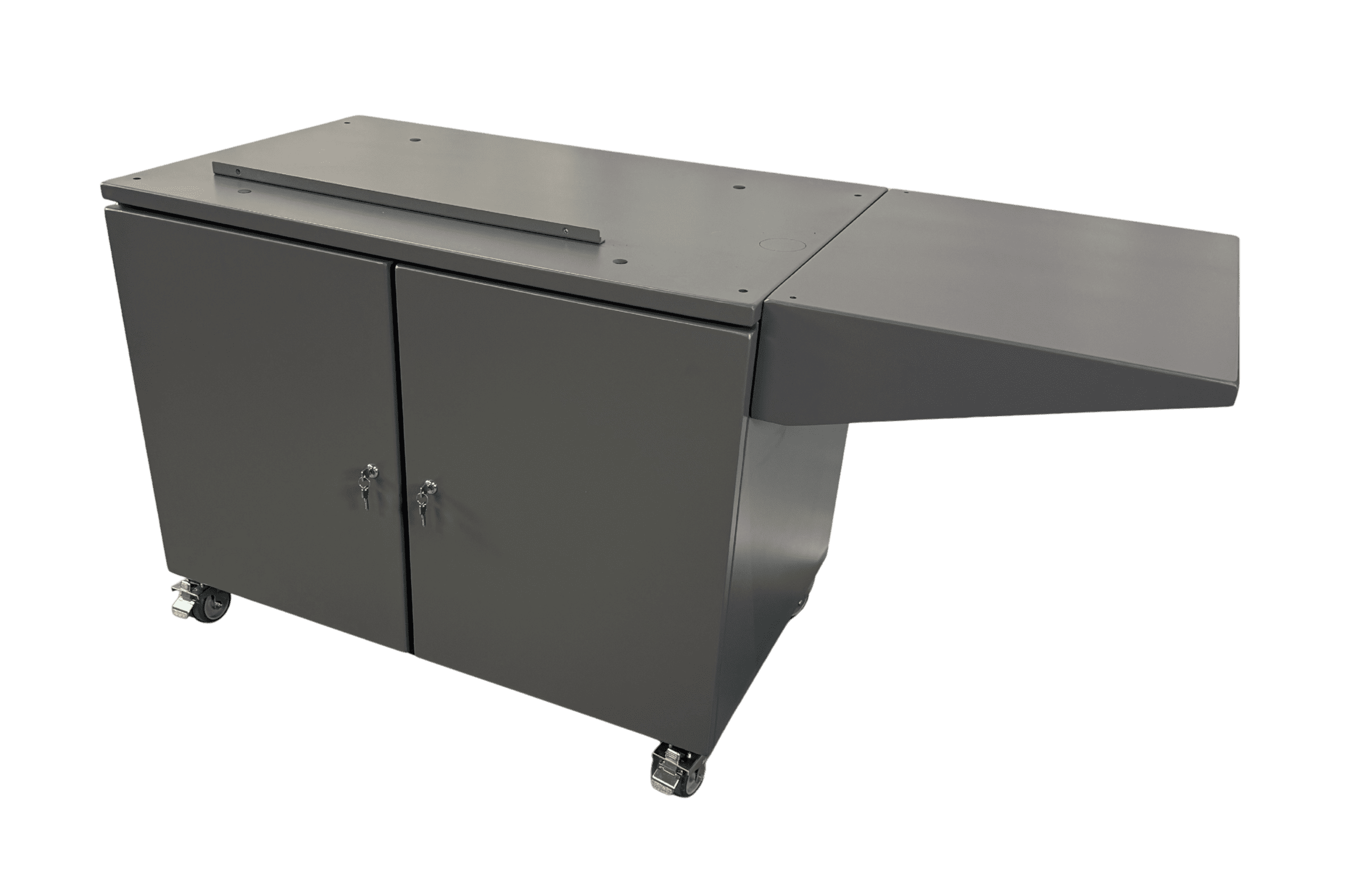

Optional accessories – Portable cabinet case (160TCLi bench top machine only)

POA

CAD/CAM Design Tools software

A single seat of Boxford CAD/CAM Design Tools is included with every machine. Features include:

- 2D design packages for turning & milling

- CAM routines to machine 2D CAD drawings & 3D CAD drawings

- Ability to lock and unlock user levels for both safety and to aid user learning

See it in action.

Which machine would you like a quote for?

Please be aware our normal working hours are 8.30 – 17.00 (GMT) Mon-Fri

Finance options available upon request.

We offer a range of finance options to help you make your next machine investment. Speak to a member of our team who will be able to help…

Call +44 (0)1422 324810